The Operations Suite consists of:

- Shift Handover.

- Autonomous Maintenance.

- Downtime Analysis.

Bridge the gap between maintenance and production

In the journey to an optimally profitable organisation, it is crucial that departments don’t operate on their own separate islands but cooperate from a single source of truth. Ultimo Operations Suite helps you bridge the gap between production and maintenance.

A brief introduction!

Shift Handover

The exchange of information is a tricky issue for many production companies. How do you make sure information is exchanged in a structured and unambiguous manner between crews and departments? Use Shift Handover to clarify agreements, problems and events. With the Shift Handover module you create a digital logbook from the Production department. The logbook and the shift logs help create transparency and a more efficient handover between shifts. Moreover, you can not only create action items for production from the shift log, but also work requests for the technical service and tasks for the Safety department. And everything is fully integrated with the module Work Order Management and the Ultimo HSE modules. Disruptions and other remarks from operators, which would not normally be saved in Ultimo, can now also be registered and linked directly to the asset structure. The teams are now both responsible for a safe work environment and the optimal availability of all machinery.

Autonomous Maintenance

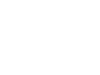

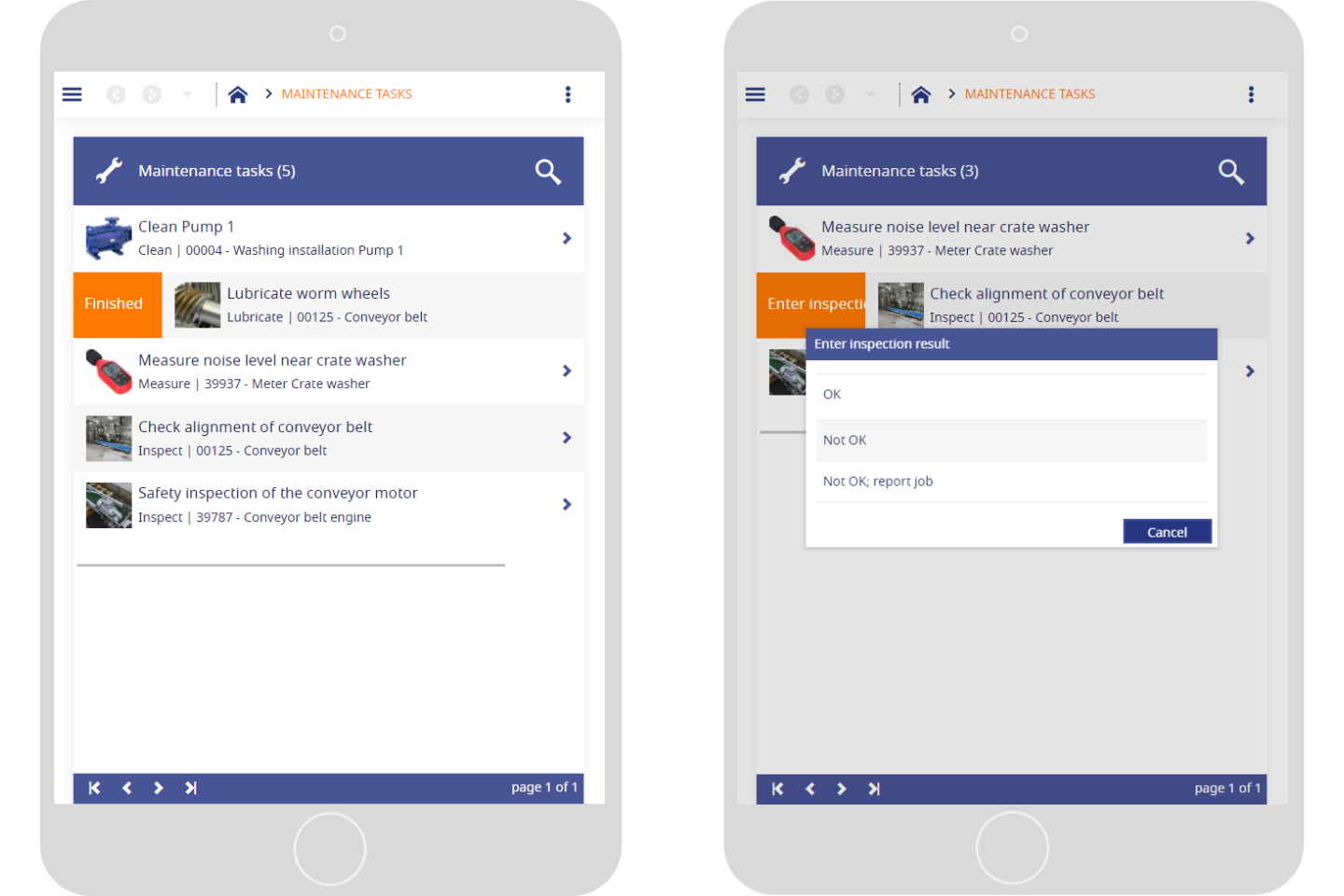

With Autonomous Maintenance in Ultimo, you offer an accessible solution for asset operators to carry out first-line maintenance. Think of cleaning, inspections, lubrications or simple repairs. These are usually actions that are carried out by operators but that are not registered in Ultimo. Or actions that can very easily be shifted from engineers to operators. With all the knowledge they have, operators can respond much quicker and without lead times, which frees up the limited capacity of the technicians for preventive and corrective maintenance. But it is important to keep an eye on these tasks and their progress. Autonomous Maintenance is an important pillar of Total Productive Maintenance, which can be shaped and observed perfectly using Ultimo.

The functionality with simple checklists and visual elements (like photos) is designed to be easy and quick to work with for operators using Ultimo on a tablet or smartphone. To increase the involvement of operators, the mobile functionality also has the option to give feedback on the tasks, for example that the instruction or photo is unclear or that the frequency should be changed. It is also possible to escalate a report to the Maintenance department. In addition to enriching the data in Ultimo, this way of working also enhances the operators’ jobs and makes the work for scarce mechanics more focused. So it’s a win-win situation.

Downtime Analysis

This feature provides an easy way of identifying downtime either by equipment operators or through an automatic import from production software. As a result you have more insight into the downtime and the production loss, and the associated costs, that may occur. The downtime data are presented clearly for customers using the standard Power BI integration in Ultimo so you can make your analyses with only a few clicks of your mouse. This way, you have high-level insight into the downtimes that lead to loss of production, and you can analyse what parts cause the most or the longest downtime. By adjusting your maintenance plan accordingly, loss of production can be driven back more effectively. This module is fully integrated in the module Shift Handover as well.

All the benefits of the Operations Suite:

- Improve collaboration between maintenance, safety and production.

- Work more efficiently because the activities are performed and registered by those most closely involved in the operation.

- A safe working environment and the best availability of the machinery.

- Enriched valuable data in your Enterprise Asset Management system so you can make even better operational and strategic decisions.

- Helps enhance the tasks of both operators and technicians, which positively influences the retention and attraction of scarce personnel.

Operations Suite part of Ultimo EAM

The Operations Suite is part of the broad Ultimo EAM platform. With the flexible Ultimo EAM platform you have a complete platform to support all of your valuable assets and the corresponding processes in your organisation. In addition to modules in the fields of maintenance, safety and operations, other features and specific industry solutions, our solutions in terms of business information and integrations complete that support.

Editions

We offer a subscription plan that meets your needs. With predefined industry solutions, we guarantee a best-practice solution for your industry. Out-of-the-Box, yet extremely flexible. Experience an unmatched ROI through quick implementations, seamless integrations and self-service application management.