A 'cool' organization

Ysco is a leading European producer of private label ice cream products, headquartered in Belgium and with a second factory in France. The company specializes in producing private label ice cream for major European retailers, producing around 190 million litres of ice creams per year, and using 26 fully automated production lines. Ysco is known for its technological automation, economies of scale and customer-focused custom solutions. After years of being part of the dairy cooperative Milcobel, Ysco was acquired by the investment funds Davidson Kempner and Afendis in 2024, with the aim of enabling further growth and international expansion.

Asset management challenges in the maintenance department

Marino Vandooren identifies three challenges he faced as the person in charge of the Maintenance department, along with some 50 colleagues:

The fear of data loss: How could the complete transfer of historical data be guaranteed? The previous Asset Management system contained a lot of customization, lacked flexibility in terms of integration and also entailed high costs.

Inefficient and incomplete reporting: Their previous system for reporting maintenance activities was cumbersome. As a result, smaller jobs were not always registered, even though they could play a crucial role in the production and quality process. More digital data collection via tablets was therefore high on the wish list.

Insufficient integration, too many systems and duplication of work: It meant that maintenance data had to be entered over and over again (for example, purchase orders for parts in an ERP system) which also increased the likelihood of potential errors.

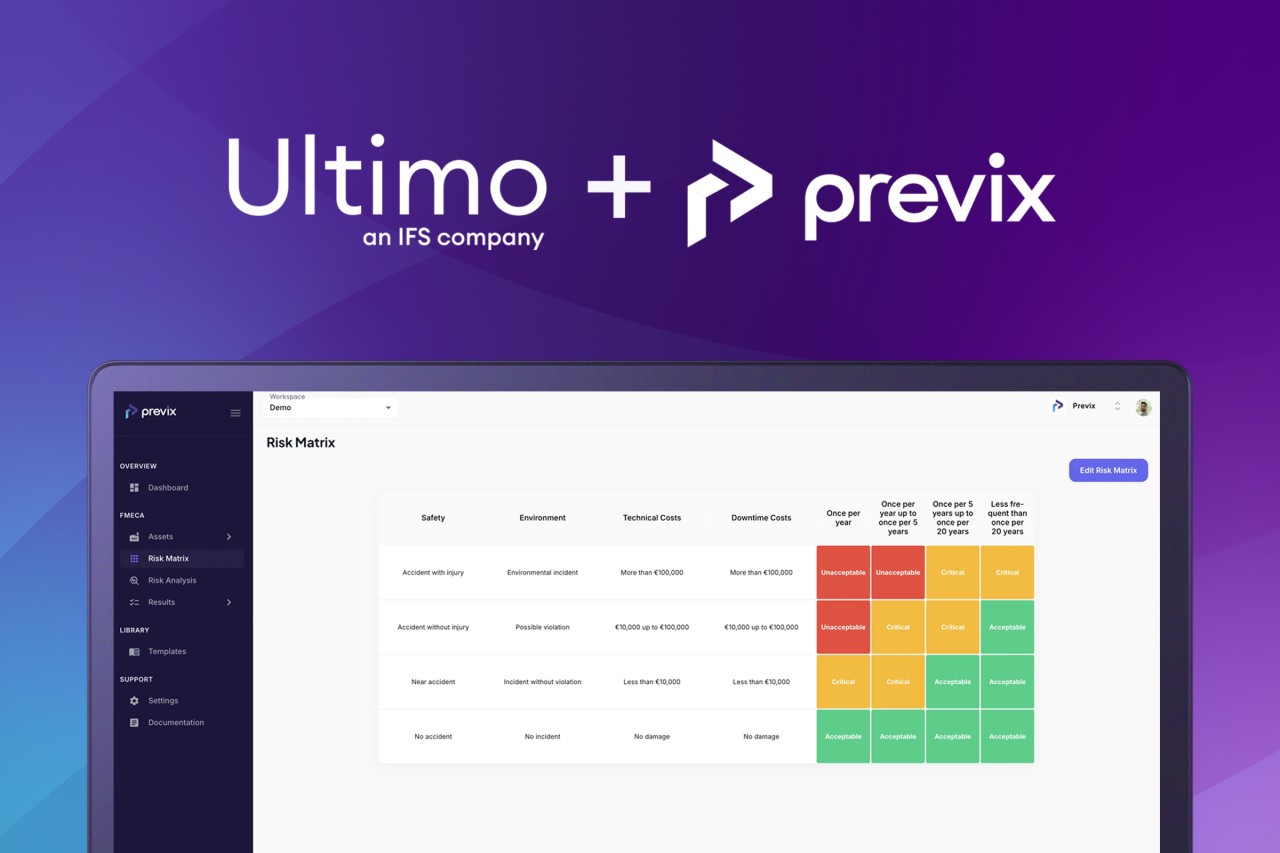

Choosing Ultimo to meet integration goals

What Marino found especially important was hearing about the experiences of other similar companies. In addition to his work for Ysco, he is also actively involved in Syntra West, a Flemish steering committee for maintenance managers: "The name Ultimo was often mentioned there, and what appealed to me was all the positive things I heard around mobility, ease of use and integration capabilities.”

When it was decided to implement Ultimo EAM at Ysco, the main goals were to adopt as much historical data on preventive maintenance, work processes, as well as current jobs (purchase orders). Marino has the following to say about this: "The project was launched in late June 2023, went live in early 2024 and was largely completed in November 2024. Of course, it took a lot of time and energy: you go from a system in which you could fill in few fields to a much more complete maintenance system, in which quality aspects are better secured. In addition, you must reach an agreement with both the vendor and your colleagues on designations and how to report. What I appreciate enormously is how I was helped by a skilled project team from Ultimo."

The Enterprise Asset Management software was also expanded to include additional EHS modules (Environment, Health, & Safety) so that Ultimo is now not only used by the Maintenance department but also by the Quality department at Ysco.

Meanwhile, Marino's technicians can scan production assets using a QR code and tablet, providing complete control over all maintenance work and purchase orders. "It's very important to mention that Ultimo has a link to our CRM system, JD Edwards from Oracle. This means, for example, that spare part orders do not have to be re-entered and the Maintenance and Administration departments are aligned. Other departments, such as the technical warehouse and our Quality department, also benefit from this integration."

Tangible results: Unlocking operational efficiency and compliance

Marino estimates that four to five standalone software packages have now been replaced by integration with JD Edwards: reduced costs through fewer vendors and customization. But there are bigger results to report:

Uptime value: improving technical efficiency: Thanks in part to the use of Ultimo, technical efficiency went from 94 to 96 percent. In a manufacturing environment that produces about 50 million gallons of ice cream a year, that 2 percent gain yields cost savings that are more in the realm of hundreds rather than tens of thousands of dollars.

Securing knowledge: All maintenance activities, large and small, are recorded. Among other things, this builds a qualitative database where technicians can see what the rest are doing. As a result, they learn from each other and team performance increases.

Efficiency: Previously, there were separate systems for maintenance requests and purchase orders. Today, this is all done in Ultimo. As an example, an EHS report comes in and a work order with the required purchase order is linked to it.

Compliance improvements: The use of tablets on the shop floor, clear work codes and wording has made the auditing process very simple and less time sensitive. Paper documents that could get lost are a thing of the past.

Next steps: looking into the future

Ultimo is expected to play an increasing role at the two production sites in Langemark, Belgium, and Argentan, France. For example, there are opportunities in the area of fleet management by setting up an additional module. After all, assets are also located outside production sites.

Let’s connect

Get your questions answered. Schedule a personalized demo to see how Ultimo can add ease and value to your business. No strings attached.