With an EAM system, companies can plan preventive maintenance; this then helps to prevent unexpected disruptions and extends the life-expectancy of the assets themselves. It also offers tools for maintaining work orders, monitoring stock levels and analyzing performance. These functions enable businesses to work more efficiently, reduce costs and improve the reliability of their assets.

In addition, software for enterprise asset management often supports integrations with other systems, such as ERP (Enterprise Resource Planning), CRM, Finance, APM, Track & Trace, AR, VR and IoT (Internet of Things), whereby real-time data and insights become available. This helps when making data-driven decisions and improves overall operational efficiency.

An EAM system that is user-friendly and flexible ensures that users will want to use the system. The fact that the system for enterprise asset management links into the organization's processes increases the likelihood that useful input will be provided by the users. This results in more valuable insights from the software.

What's included in Enterprise Asset Management?

If you take the term "asset management" literally, it means the management of physical assets within and outside the confines of an organization. From acquisition and commissioning to de-commissioning and disposal. Asset management software can support this entire process. The aim should be to use your assets in a safe and efficient manner, throughout their useful life. With maximum input and the lowest possible maintenance costs over their life-cycle. Once that's the case, you are complying with the definition of asset management.

When considering which processes are supported by Enterprise Asset Management, these include:

Maintenance Management: in the broadest sense of the term. From corrective and preventive maintenance to predictive maintenance. With a focus on work order management, maintenance planning, asset tracking and monitoring, contract management, stock management and purchasing.

Health, Safety & Environment: your assets function most effectively if they are used in a safe and sustainable environment. Moreover, your employees must carry out their work in a safe environment and you must comply with stringent regulations in relation to employment and the environment. Asset management software should ideally support these processes:

Operations: by directly involving operators on the work floor in your asset management tasks, you create a useful extension of your day-to-day operation. Simple tasks can be carried out on site, and downtime can be recorded accurately for improved analysis.

Reliability: to improve the safety and reliability of your assets and production processes, it is essential to use the insights from reliability engineers. Functionality with respect to reliability substantially increases the value of your EAM system.

Business information/intelligence: solutions for Enterprise Asset Management (EAM) centralize important operational data, which then provides insights to support the decision-making processes of managers and directors.

All these processes can be supported by a modern asset management system. Mobile options and AI applications simplify the corresponding work.

While EAM is not a new concept, it is experiencing a huge jump in capability from a technology standpoint. With advancements in technology, such as the Internet of Things (IoT), AI and predictive analytics, EAM has become more effective, enabling organizations to collect and analyze large amounts of data from assets in real-time, and move towards proactive maintenance and optimization strategies. As a result, asset management strategies are more aligned with broader business objectives. This warrants a closer look at how EAM can best be linked to strategic goals.

How does EAM software work in practice?

In order to implement EAM software, you usually introduce the asset management process in stages. This is a logical element in the full asset management life-cycle. This allows you to follow the operations of EAM software in practice:

Installation and configuration: begin by installing the software and set this up according to your organization's needs.

Asset registration: add all physical assets to the system, including details such as location, serial numbers, purchase date and maintenance history.

Maintenance planning: set up schedules for preventive and predictive maintenance to prevent disruption and extend the life span of your assets.

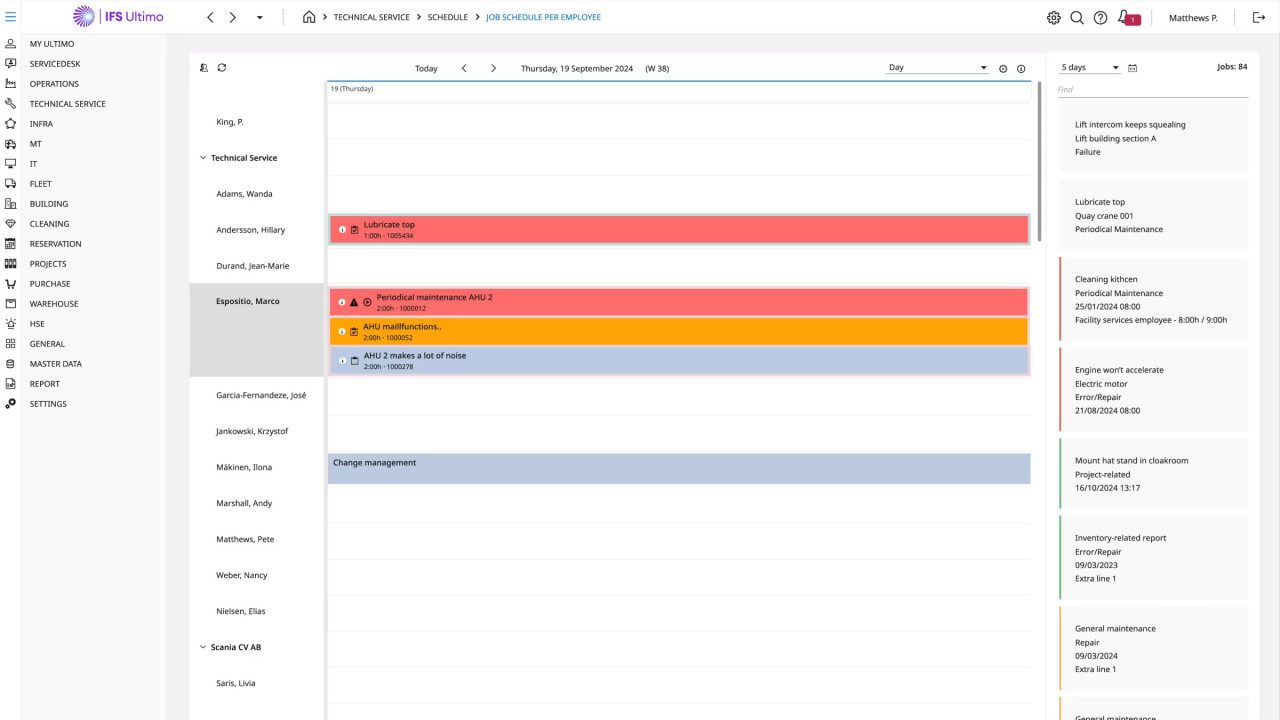

Work order management: create work orders and allocate these to technicians. Follow the progress of maintenance tasks and track which parts and tools are needed.

Real-time Monitoring: use sensors and IoT integrations to monitor asset performance in real-time and identify potential problems promptly.

Reporting and analysis: generate reports and analyze data to gain insights into the performance of assets, maintenance costs and compliance with regulations.

Mobile access: technicians can gain access to work orders, maintenance history and asset details via mobile devices, improving their efficiency in the field.

Integration with other systems: integrate EAM software with ERP systems and other business applications to centralize data and streamline workflows.

EAM Maturity Model

IFS Ultimo has set up its own EAM Maturity Model. Make the change from responding to short-term challenges to proactive planning for long-term goals.

The EAM Maturity Model has been created to help you improve your asset management strategies. Identify where in the asset management process you are currently located and evaluate where you want to end up.

What are the benefits of EAM software?

EAM software, as an automated maintenance system, offers tangible benefits which improve the efficiency and effectiveness of asset management:

Better performance of assets: real-time monitoring can ensure inefficiencies are quickly tracked and tackled. This expands asset management efficiency.

Reduce maintenance costs by 10%: smart preventive/predictive maintenance management reduces the percentage of corrective maintenance. This helps to reduce maintenance costs.

Longer life span for assets: proactive maintenance reduces wear and tear and prevents expensive repairs, allowing assets to last for longer.

Lower downtime: real-time reports help prevent unexpected interruptions, increasing productivity. Reduce downtime by 40% like Kisuma Chemicals and by 30% like Dr. Schär.

Compliance with regulations and safety: by monitoring assets and ensuring that they fulfil all safety standards, companies can avoid fines and legal problems.

Optimized use of resources: insights into asset usage helps to identify under-used assets and ensure the more efficient use of resources.

Save on inventory costs and spare parts costs: Smart inventory management and keeping track of spare parts can lead to significant savings. For example, NewCold saved more than £95,000 by using EAM software.

Makes work more pleasant: working with state-of-the-art technology makes working in enterprise asset management more pleasant and challenging. You are learning something new every day. This also means you are more effective.

Who can use EAM software?

Asset managers and maintenance managers in the following sectors can benefit most from EAM software:

Production companies: these companies use EAM software to manage machinery and production lines, helping minimize downtime and increase efficiency.

Food & Beverage: boost production, asset performance, and compliance with an advanced, centralized EAM solution for efficient Food & Beverage operations.

Energy and utility companies: companies in the energy, water and waste management industries use EAM to maintain and optimize their infrastructure, essential to ensure a reliable service.

Transport and logistics: these sectors benefit from EAM software for the management of vehicle fleets, railways, sea ports and airports, and operational efficiency and safety are increased as a result.

Healthcare: hospitals and care organizations use EAM to manage medical equipment and facilities, supporting compliance with regulations and the safety of patients.

Government and public sector: government bodies use EAM to manage buildings, infrastructure and other public assets, helping to optimize resources and improve the service provided to citizens.

Mining and raw materials: companies in these sectors use EAM to manage heavy machinery and equipment, essential for the safety and efficiency of their operations.

Maintenance managers in other sectors, where expensive assets are used, could also benefit from the use of software to effectively support maintenance and asset management.

What are the key strengths of Ultimo EAM software?

Unmatched time to value. No more trying to justify ROI. Ultimo delivers measurable value at unmatched speed. Rapidly deployed and easily adopted - all with a flexible pricing model.

Increased asset performance, decreased admin time. Time to expect better outcomes. Ultimo’s integrated solution has advanced analytics, innovative maintenance and planning tools, and collaboration features for more impact and efficiency.

Easy to adopt, use, and master. Empower your teams. Ultimo is a flexible, scalable, user-friendly tool. It has unmatched e-learning resources to enhance adoption and team performance.

What are the modern capabilities of Ultimo EAM software?

Ultimo EAM is a cutting‑edge enterprise asset management solution that unites asset lifecycle control—from acquisition to disposal—all through an intuitive, user‑friendly platform that empowers collaboration, compliance, and safety. Its cloud‑native architecture leverages Microsoft Azure to ensure around‑the‑clock performance (99.98 % average uptime), proactive monitoring, continuous updates, strong security, and seamless enhancements via continuous delivery.

AI: Ultimo embeds agentic, “digital coworker” AI that doesn’t just analyze—it acts. This includes autonomous EHS incident reporting and AI‑assisted work‑order scheduling, which boosts safety, minimizes reactive maintenance, and accelerates decision‑making without requiring complex integrations. The platform also has plans for AI‑driven smart asset cataloging and scheduling assistance .

IoT & Analytics: Via strong integration capabilities, Ultimo supports IoT/OT systems (and SCADA, BIM, CAD, and more), enabling real‑time visibility and smarter workflows. Dashboards and analytics provide actionable insights that improve operational efficiency and asset uptime.

Mobile: The native cloud‑based mobile solution ensures field teams have full access—online or offline—to asset data, streamlining hands‑on tooling time and reducing administrative friction.

In sum, Ultimo delivers a modern EAM experience where AI‑empowered workflows, IoT‑driven insights, and responsive mobile access converge to transform maintenance into a proactive, efficient, and future‑ready operation.

What are trends in Enterprise Asset Management?

The Ultimo Maintenance Trend Report highlights the latest trends shaping the asset management industry. Packed with current insights, it empowers maintenance and asset management professionals to turn today’s challenges into tomorrow’s drivers of innovation and digital transformation.

When asked about the trends that will have the greatest impact, organizations identified the aging workforce as the top concern (63%), underscoring the urgency of knowledge transfer and workforce planning. ESG pressures followed closely (43%), reflecting growing accountability around sustainability. New to this year’s survey, supply chain disruption emerged as a rising issue (34%), highlighting its increasing influence on operational resilience and strategic planning.

Best-of-breed EAM software

Frequently Asked Questions

-

With EAM software, companies can centralize their assets, making it easier to monitor, optimize, and proactively inspect and maintain them. This helps prevent unplanned downtime, suboptimal asset performance, and supply shortages.

-

With EAM software, it is possible to manage many different company assets. This could include physical assets, such as machinery and equipment, vehicles, buildings and the corresponding facilities. When it comes to infrastructure, it might include physical assets such as utility infrastructure, infrastructural objects and transport networks. However, IT resources and medical devices are also commonly-used assets in EAM software. In addition to these types, EAM asset management is also ideal for managing inventories, spare parts, work schedules for the Technical Service, skills, certifications and permits.

-

Integrating EAM software accelerates the digital transformation of your organization. The following asset integrations are currently often used:

Integration with ERP

Link to IoT Internet of Things

Augmented Reality

Asset Performance Management

CAD/BIM

GIS

AI

Document management systems

HR systems

Business Intelligence

Operational equipment or systems