The logistics sector is at a breaking point. Global supply chains are still recovering from recent disruptions, while customer expectations for faster, cheaper, and more sustainable delivery continue to climb. Behind every late shipment and service failure lies a simple truth: asset downtime is costing the industry billions. Research from Deloitte shows that unplanned downtime costs industrial manufacturers an estimated $50 billion annually, with logistics operations facing similar pressure as they manage increasingly complex fleets across multiple transportation modes.

This presents an opportunity: the same digital technologies transforming how we move goods are revolutionizing how we maintain the assets that keep logistics running. As we look toward 2026, artificial intelligence (AI), Internet of Things (IoT) technology, and advanced analytics are converging to create maintenance systems that don't just help fix problems but prevent them entirely. For asset managers in logistics, the question isn't whether to adopt these technologies, but how quickly you can implement them before your competitors do.

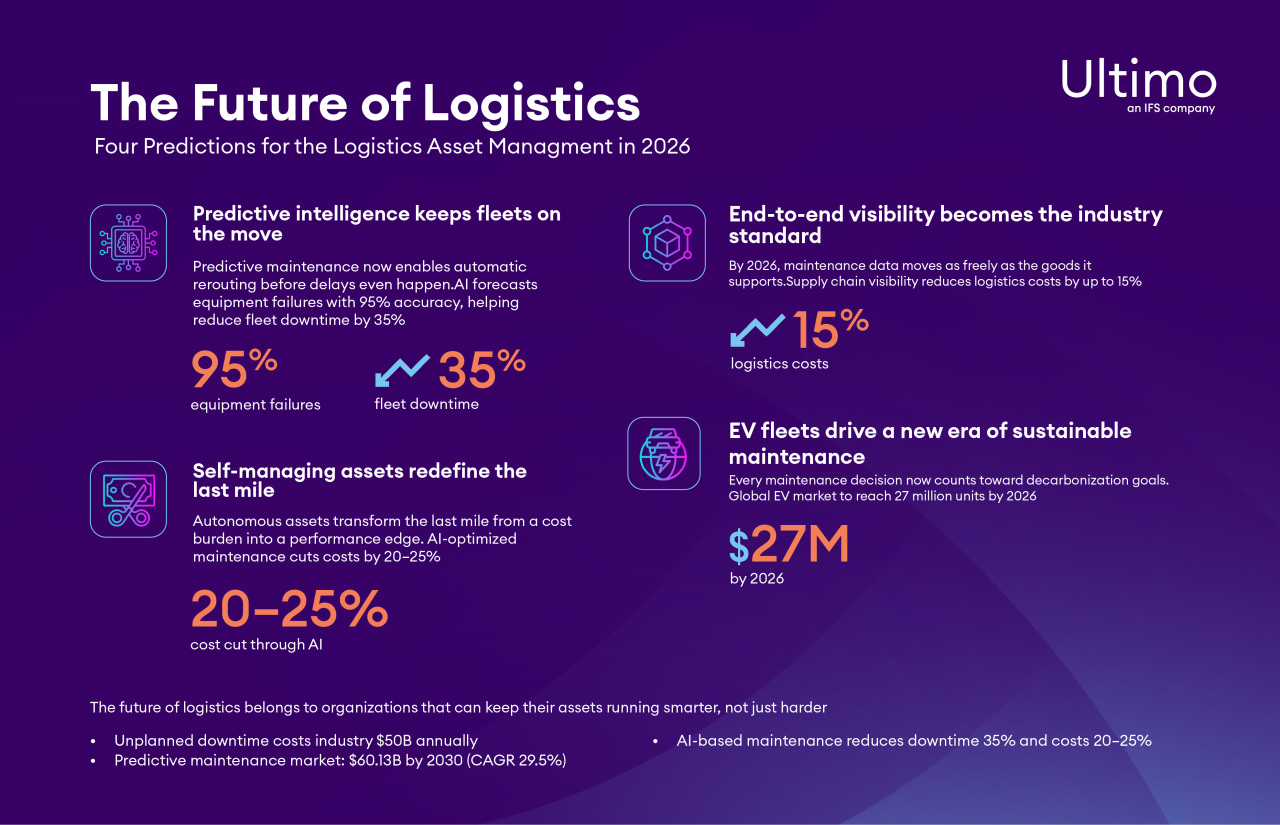

1. Fleet-Wide Predictive Maintenance and Dynamic Routing

Predictive maintenance is entering a new phase of maturity in 2026. AI-driven predictive maintenance systems can now forecast failures with 95 percent accuracy, reducing fleet downtime by 35 percent and enabling automatic rerouting of shipments to prevent delays1. According to Grand View Research, the global predictive maintenance market is projected to reach $60.13 billion by 2030, growing at a CAGR of 29.5 percent.

Real-time telematics data from trucks, ships, planes, and warehouse equipment will support confident maintenance decisions. Dynamic scheduling will coordinate maintenance windows with delivery routes to minimize downtime and maximize asset utilization. This represents a significant evolution from last year's predictions, where we focused primarily on integration challenges. In 2025, we discussed how "the challenge lies not in the technology itself, but in creating integrated systems" between maintenance and operations teams. Now, those integrations are becoming standard, with multi-modal asset health monitoring enabling seamless handoffs between transportation modes from truck to rail to ship.

2. Autonomous Asset Management for Last-Mile Operations

The last mile has always been logistics' most expensive challenge, but autonomous asset management is changing the equation. Self-diagnosing delivery vehicles and drones will automatically schedule their own maintenance windows, while warehouse robotics and automated sorting systems perform self-maintenance and request human intervention only when necessary.

Studies indicate that AI-optimized maintenance can reduce operational costs by 20 to 25 percent through improved asset availability and reduced emergency repairs. This cost reduction is critical during peak seasons. Asset failure during holidays and e-commerce surges can mean the difference between making a profit or suffering a loss. The automation extends beyond individual assets to entire last-mile ecosystems, where delivery vehicles, sorting equipment, and even charging infrastructure communicate to optimize uptime.

3. Supply Chain Visibility and Asset Synchronization

End-to-end visibility has moved from aspiration to requirement. In 2026, real-time asset tracking will provide complete visibility of maintenance needs across global logistics networks. Coordinated maintenance scheduling across ports, distribution centers, airports and transportation fleets will prevent the bottlenecks that cascade through supply chains.

Research from McKinsey shows that supply chain visibility can reduce logistics costs by up to 15 percent while improving customer satisfaction through more reliable delivery windows. Asset performance data will be shared not just internally but with shippers for proactive logistics planning. Global standardization of maintenance protocols will enable seamless asset transfers between logistics partners, breaking down the silos that have historically fragmented maintenance operations.

This represents significant progress from our 2025 outlook, where we emphasized the need for better data integration. The difference now is that these systems are interconnected by default rather than requiring custom integration projects.

4. Sustainability and the Energy Transition

Perhaps no trend will reshape logistics maintenance more profoundly than the shift to electric vehicle (EV) fleets and the broader energy transition. Emissions monitoring and fuel efficiency optimization will be integrated into every maintenance decision, while automated compliance reporting handles international environmental regulations across different jurisdictions.

According to Bloomberg, the global electric vehicle market is expected to reach 27 million units by 2026, with commercial fleets representing a rapidly growing segment. Battery health monitoring and charging infrastructure optimization will become core maintenance competencies. Carbon footprint tracking at the asset level will add depth to the repair or replace conundrum around aging logistics equipment.

European Union regulations mandating a 55 percent reduction in transport emissions by 2030 are forcing logistics operators to accelerate fleet electrification and optimize energy consumption across all operations. The maintenance implications are enormous: technicians need new skills for electric drivetrains, charging infrastructure requires its own maintenance protocols, and battery degradation patterns must be monitored to prevent range anxiety in delivery operations.

These predictions point toward a future where maintenance isn't a cost center but a strategic advantage. The question is whether your organization is ready. Ultimo’s EAM Maturity Model helps logistics operators understand exactly where they stand and what steps will deliver the greatest impact.

Book a demo with Ultimo today to discover where you are on your asset maintenance journey and build a roadmap to 2026 and beyond. On the road to the future, those that can keep their assets running smarter will lead the way.