Operating round the clock

Kisuma Chemicals, part of the Japanese Kyowa Group, produces high-quality additives for the polymer production and processing industry. They have four production lines that operate round the clock.

Work safety to a higher lever

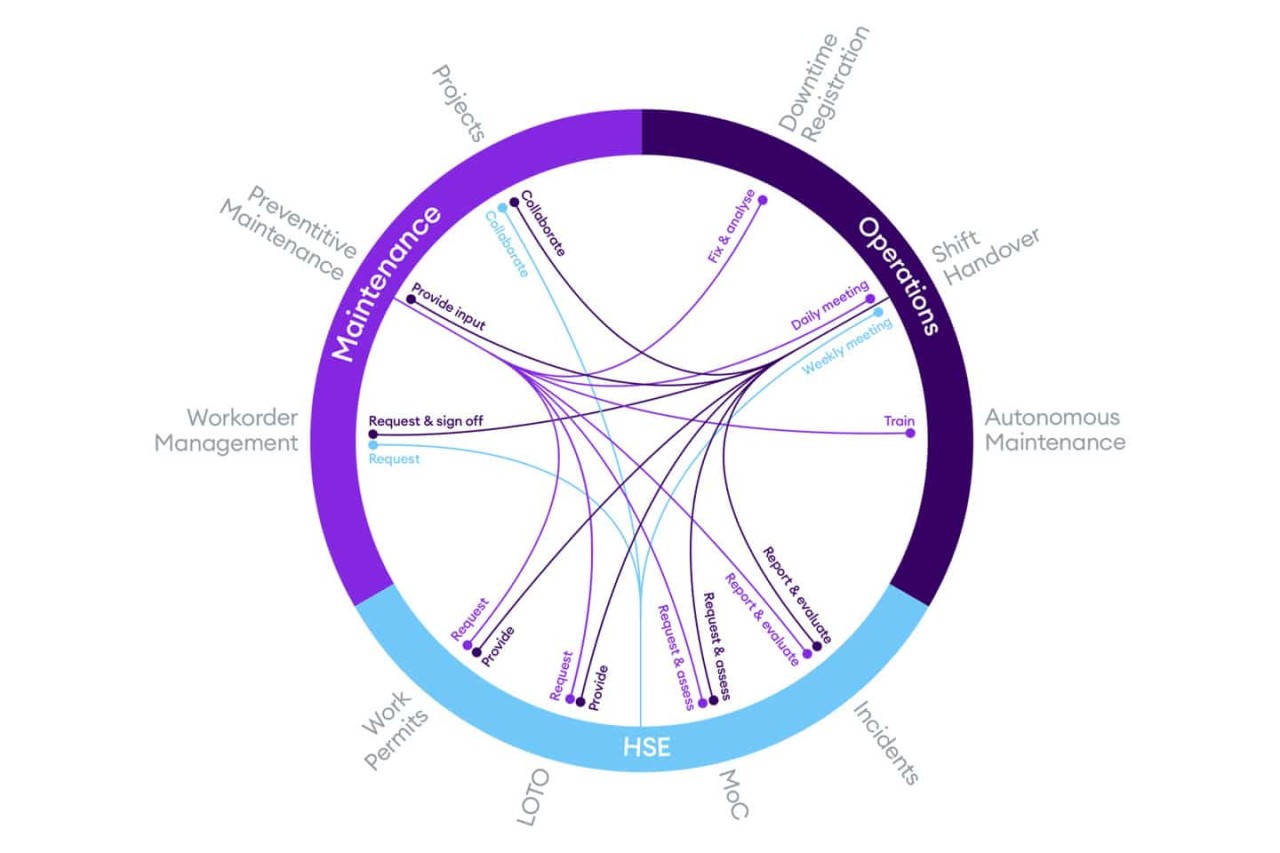

All because of a well thought-out FMECA strategy and its professional registration in Ultimo. Simultaneously, they have also lifted work safety to a higher level with the broad use of different HSE modules. Kisuma Chemicals now views its assets as a revenue model instead of an expense.

Let’s connect

Get your questions answered. Schedule a personalized demo to see how Ultimo can add ease and value to your business. No strings attached.