The asset maintenance landscape is undergoing its most significant transformation in decades. As I speak with operations leaders, facility managers, and maintenance professionals across industries, one thing becomes crystal clear: we are standing at the threshold of a new era. The convergence of artificial intelligence (AI), sustainability imperatives, workforce evolution, and enterprise-wide data integration is reshaping how organizations manage their most critical assets. The question is no longer whether these changes will happen, but how prepared your organization is to embrace them.

Based on my conversations with industry leaders and analysis of emerging trends, here are four predictions that will define asset maintenance in 2026 and beyond.

1. AI Becomes the New Norm

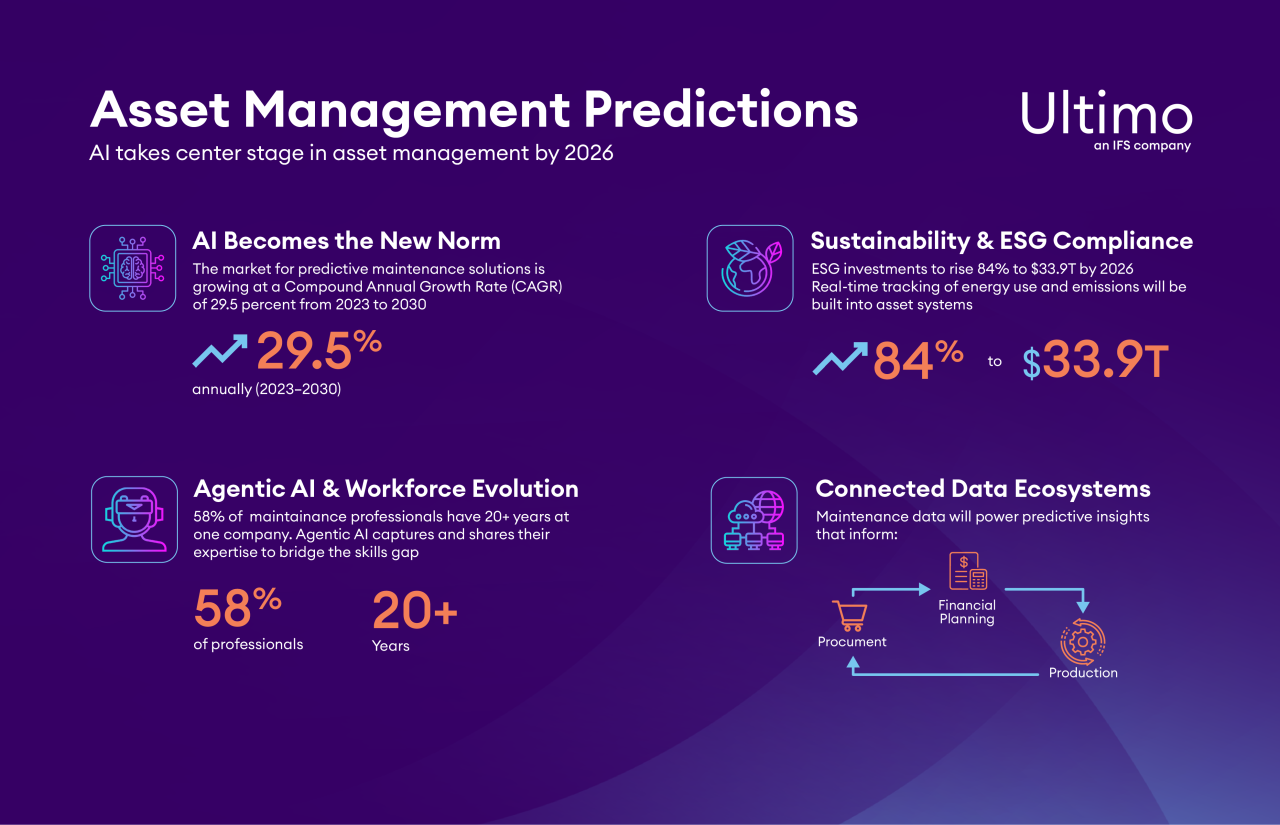

The predictive maintenance market is experiencing explosive growth. Valued at $7.85 billion in 2022, the global predictive maintenance market is expected to grow at a Compound Annual Growth Rate of 29.5 percent from 2023 to 20301. But 2026 will mark a critical inflection point where AI shifts from a future-facing ambition to a standard operating procedure.

Advanced machine learning algorithms will soon be able to predict equipment failures 6 to 12 months in advance with accuracy rates exceeding 85 percent2. This represents a quantum leap from current capabilities. When implemented properly, Internet of Things (IoT) powered predictive maintenance can achieve prediction accuracies above 90 percent3, and this precision will only improve as more data becomes available.

The integration of IoT sensors, digital twins, and AI will create a comprehensive asset health monitoring ecosystem that provides real-time insights into equipment conditions. This shift from time-based to condition-based maintenance strategies will reduce costs by 20 to 30 percent4, while real-time optimization adjusts maintenance schedules based on actual usage patterns and environmental factors rather than arbitrary calendar intervals.

What distinguishes 2026 from previous years is that AI will extend far beyond predictive maintenance. It will influence procurement decisions, optimize spare parts management, recommend replacement versus repair strategies, and even predict the financial impact of maintenance decisions on overall business performance. The technology that was once considered cutting-edge will become table stakes.

2. Agentic AI and Skills Transformation

The maintenance workforce is evolving rapidly, and technology is not replacing humans but rather augmenting their capabilities. The global augmented reality market size was estimated at $83.65 billion in 2024 and is expected to grow at a CAGR of 37.9 percent from 2025 to 2030, with maintenance and field service representing major adoption areas5.

Augmented reality (AR) will guide technicians through complex repairs and inspections, overlaying digital information onto physical equipment. A junior technician wearing AR glasses will have access to the same expertise as a 20-year veteran, with step-by-step visual instructions, real-time remote expert guidance, and instant access to technical documentation.

As experienced maintenance professionals retire, they take with them decades of institutional knowledge and hard-won expertise that cannot be easily replaced through traditional training methods. This creates a critical knowledge equity problem: newer technicians lack access to the deep understanding that senior experts developed over entire careers, leading to capability gaps that threaten operational continuity.

Agentic AI systems offer a pathway to democratize this expertise before it disappears. By capturing the diagnostic patterns, troubleshooting logic, and contextual decision-making of retiring professionals, these systems can create a baseline understanding accessible to all technicians regardless of their experience level. Rather than knowledge remaining siloed in the minds of a few aging experts, it becomes distributed equity—a shared resource that elevates the entire workforce.

This addresses not just the skills shortage, but the fundamental inequity of knowledge distribution. Junior technicians gain immediate access to expert-level guidance for complex problems, while mid-career professionals can handle situations that previously required decades of experience. The result is a more resilient maintenance organization where capability is no longer concentrated in a shrinking cohort of senior staff, but embedded in systems that ensure every technician, regardless of tenure or background, can perform at a consistently high level.

The younger workforce entering the field expects a mobile-first, intuitive interface for work order management. They have grown up with smartphones and cloud-based applications, and they will demand the same user experience at work. Organizations clinging to outdated, desktop-only systems will struggle to attract and retain talent.

Hybrid human-AI teams will become the norm, with AI handling routine data analysis, anomaly detection, and pattern recognition while human expertise can focus on strategic decisions, complex problem-solving, and relationship management. This partnership will unlock productivity gains that neither could achieve alone.

3. Sustainability and ESG Compliance Integration

Environmental, social, and governance (ESG) considerations are no longer peripheral concerns. They are central to operational strategy and asset management decisions. ESG-focused institutional investment is seen soaring 84 percent to $33.9 trillion in 2026, representing 21.5 percent of assets under management5. This massive capital shift means that asset maintenance platforms must evolve to meet stringent sustainability requirements.

In 2026, leading enterprise asset management (EAM) platforms will track carbon footprint and energy efficiency metrics in real-time at the asset level. By 2026, all ESG data will need to be digitally tagged, enhancing data comparability and accessibility. This regulatory requirement will drive widespread adoption of sustainability tracking within maintenance management systems.

Circular economy principles will lead decisions impact the asset lifecycle. Environmental impact, carbon emissions, and the availability of sustainable replacement parts all play a major role in deciding to repair or replace. Green maintenance practices, from eco-friendly lubricants to sustainable part sourcing, will transform from nice-to-have differentiators into competitive necessities.

The most forward-thinking organizations will use their asset management systems to generate automated sustainability reports that demonstrate compliance with increasingly stringent regulatory requirements while also showcasing their environmental stewardship to investors and customers.

4. Integrated Enterprise Ecosystems and Data Democratization

The era of siloed systems is ending. In 2026, EAM platforms will form a key node in an integrated digital ecosystem, connecting effortlessly with enterprise resource planning (ERP), supply chain, and financial systems to enable enterprise-wide intelligence. Asset health data will flow seamlessly across organizational boundaries, influencing decisions far beyond the maintenance department.

Real-time asset performance data will inform procurement strategies, determining optimal reorder points for critical spare parts. Production scheduling will adjust automatically based on equipment availability and condition. Financial planning will incorporate predictive maintenance forecasts to model capital expenditure requirements with unprecedented accuracy.

Self-service analytics will empower non-technical users to generate insights from maintenance data without requiring specialized training or IT support. Operations managers, financial analysts, and executive leaders will all access the same underlying data, each viewing it through lenses relevant to their responsibilities.

Cross-functional teams will use shared asset data for strategic business decisions that extend well beyond traditional maintenance activities. Should we expand production capacity or maximize utilization of existing assets? The answer will emerge from integrated data that spans maintenance history, financial performance, sustainability metrics, and market demand forecasts.

This data democratization represents a fundamental shift in how organizations approach asset management. Maintenance data will no longer live in isolation but will become a core component of enterprise-wide business intelligence.

Transformed Asset Maintenance Strategies

These predictions paint a picture of an asset maintenance landscape that is more intelligent, sustainable, integrated, and human-centered than ever before. But transformation does not happen by accident. It requires strategic planning, the right technology foundation, and a clear understanding of where your organization stands today.

Ultimo’s proprietary EAM Maturity Model provides a framework for assessing your current asset maintenance capabilities and charting a path forward. Whether you are just beginning to digitize work orders or already leveraging advanced predictive analytics, understanding your position on this journey is the first step toward realizing the benefits outlined in these predictions.

Book a demo with Ultimo today to discover where you are on your asset maintenance journey and develop a roadmap for reaching the next level. The future of asset maintenance is here. The only question is whether you will lead it or follow it.